|

Dec

18

2023

|

|

Posted 2 years 70 days ago ago by Admin

|

|

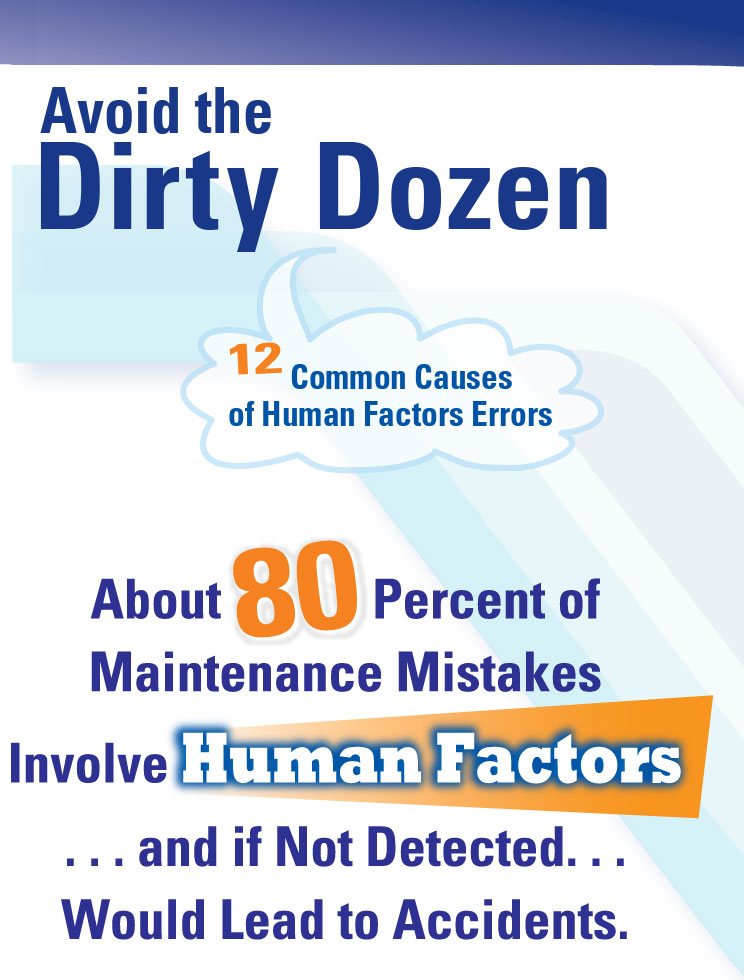

There is a monster in the hangar. I’m not sure how it got in but it’s high time it left. The monster’s name is Distractions. We must focus to minimize and eliminate Distractions, or it can be financially costly or even dangerous. The Aviation Human Factors Dirty Dozen listed on www.FAASafety.gov defines distractions as anything that draws your attention away from the task at hand. It goes on to say that distractions are the number one cause of forgetting things, including what has or has not been done in a maintenance task.

Working as an aircraft maintenance professional, our intention is to create a culture of safety. However, it’s our lack of attention that usually dictates whether maintenance items are overlooked or forgotten. Interruptions are a prime source of distraction. Once the train of thought is broken it’s imperative that we begin again exactly where we left off. From my personal observation I’d say cell phones are in the top two, if not number one, as a major distraction. It is my opinion that mechanics should not be allowed to wear earbuds or use phones when performing maintenance. It can be argued that a smartphone is another tool for the job, but when a text or email sounds a ping, you are distracted at that point. Lockers for phones during work times is one recommendation for ensuring that a notification will not become a distraction.

Most aircraft maintenance companies have put in place some good safety nets such as secondary maintenance checks (SMC), going back three steps when restarting the work, using a checklist, as well as many other rules, regulations, policies and procedures. All of these are important, but I want us to look at prevention. Benjamin Franklin said, “An ounce of prevention is worth a pound of cure.”

If we focus our attention on our intentions; we can minimize distractions that could cause issues. Our intentions should be for everyone to be safe and to maintain our equipment properly,

First and foremost, it is the mechanic’s responsibility to complete all maintenance items to the OEM standard and FAA requirements. The mechanic or installer must practice self-discipline, maintain focus and minimize interruptions to ensure that all flight control bolts are tight and keyed, all fuel, oil and hydraulic lines are tight with no signs of leaking, and that the aircraft is serviced properly to standard.

The final step should be to get someone to inspect the work before considering the job completed.

At our facility we rely on ‘the dirty dozen.’ Here are some of the ways that we incorporate them in our daily work. Everyone, including the administrative team, is required to take the dirty- dozen annual training. A Safety Committee has been appointed and every Monday morning we discuss safety and compliance. That includes anything that may be considered a distraction. Additional training is attended with the Aeronautical Repair Station Association (ARSA), and we observe a periodic safety stand down.

Safety must be intentional. That requires a conscious deliberate decision to eliminate distractions, to maintain our focus and keep our attention on the task at hand so that everyone goes home safely at the end of the day.

READ MORE ROTOR PRO: https://justhelicopters.com/Magazine

WATCH ROTOR PRO YOUTUBE CHANNEL: https://buff.ly/3Md0T3y

You can also find us on

Instagram - https://www.instagram.com/rotorpro1

Facebook - https://www.facebook.com/rotorpro1

Twitter - https://twitter.com/justhelicopters

LinkedIn - https://www.linkedin.com/company/rotorpro1