|

Oct

03

2022

|

|

Posted 3 years 148 days ago ago by Admin

|

|

If you’ve ever witnessed a wildfire, you’ve likely seen the ubiquitous Bambi Bucket® dropping water on bright orange flames. The product turns 40 this year, and it has grown in both size and function over the decades. In this article, learn more about the product that has a simple appearance, but high visibility. It's garnered a tremendous international customer base and its popularity is continuing to grow with an increase in severe wildfires.

SEI Industries of British Columbia, Canada, produces Bambi Bucket®. They have other product lines as well, such as military fuel systems and aviation transport systems, to name a couple. General Manager Mark Tayler has been with the company for 18 years, and said that they have popular products that solve a problem for helicopter operators in military and fire service applications. He added that their success is in their employees and how the company is managed.

The employee base is sitting at about 100, even after 40 years, and Tayler said a key to the company’s success is that they care. “We care about employees, customers, and supplier networks. If we aren’t living it, we ask our employees to call us out. Those values are posted when you walk in the front door and employees see it when they walk into the business. He added, “If you have a group of happy people when the management cares about them, they deliver and make better decisions.”

Worldwide influence and need

Good decisions can be mission-critical when considering the intense nature of their work. They have customers in Canada, United States, Turkey, Greece, Portugal, Spain, Indonesia, and Australia to name a few globe-spanning locations.

Tayler said that wildfires have become more severe, so customers of the Bambi Bucket® are vigilant about their firefighting tools. “Wildfires are becoming more common internationally. The duration and intensity of the fire seasons appears to be growing over time. This could be due to global warming and seems to be more prominent over the last five years.”

Beginning

Tayler said that the product had success initially because it was a “dramatic improvement over the historic solid, plastic buckets available that had to be delivered by truck to the fire location or flown slowly while slung below the helicopter.”

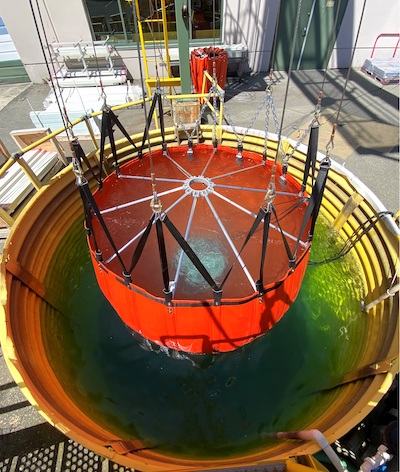

The flexible, collapsible, Bambi Bucket® was introduced in 1982 and it allowed helicopter operators to load the collapsed bucket directly inside the aircraft and quickly fly to the fire. Once at the fire, they would deploy the bucket, attach it to the hook and start firefighting.

Tayler said, “SEI has had continued success over the years as we have adapted the Bambi Bucket® product and service over time based on feedback from customers and we have grown continually to meet customer demand. Product improvements include multi-drop capability, ‘Powerfill’ accessories, and foam dispensing options. Service improvements include adding international service centers and expanding internationally with many in-country agents supporting customers.”

Company founder and inventor of the Bambi Bucket®, Don Arney, is considered, “a relentless inventor that is constantly thinking of new ideas for the Bambi Bucket® as well as other product ideas in a very broad area of topics,” said Tayler. Now 75, Arney no longer works in the business day-to-day, but does participate as chairman of the board, and takes a strong interest in research and development, Tayler said.

Customer insights

One long-term customer is Andre Hutchings, director of operations for Volo Mission, an external load/aerial fire training company. He is also a command pilot for Columbia Helicopters. He said, “Columbia Helicopters have been a customer of SEI for over 26 years, Volo Mission has been a customer of SEI for 10 years and I have been flying different model Bambi Buckets for over 24 years.”

For him, he said that Bambi Buckets® are number one in their industry, “They work as advertised, they are reliable, durable and simple to use from a pilot’s perspective. There are models, sizes, and options for all helicopters, and they are easy to maintain, care for and repair in the field for your maintenance teams. If looked after and stored correctly, as per the SEI ops and service manuals, they will be a crucial tool in your kit for many years.”

SEI Technical Salesperson Ryan Spilchen said, “Customers comment that they love how tough and dependable the products are.” He said it is not uncommon for customers to purchase two Bambi Buckets per helicopter to comply with contracts. He said the size of the agency or organization will denote how many they buy overall, but said some customers can have hundreds of buckets to outfit all of their helicopters. Spilchen added that the U.S. market seems to have the greatest need now because of the intensity of the fire seasons.

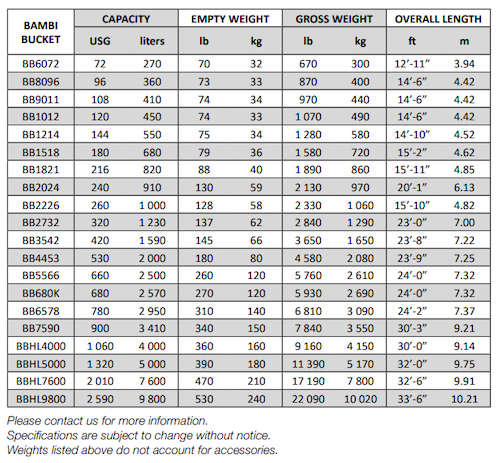

Hutchings recalls a couple of significant fire seasons where the Bambi Bucket® was especially useful. “One of the most memorable Bambi Bucket® experiences for me was an urban fire on the outskirts of Redding, California, where there were literally fires in the streets (that were) burning homes and other structures. We were using a 2,000-gallon Bambi Bucket® and people were out waving at us to drop on their homes. It was surreal, we dropped a lot of water that day and saved a lot of homes and buildings,” he said.

Another time in 2021, he was in Turkey fighting a fire in a Columbia Chinook using a 2,600-gallon Bambi Torrentula bucket with a power-fill option. He said it carried 22,000 pounds of water, “literally a swimming pool. The Turkish fire managers and fire crews had never seen a bucket with the ability to make multiple drops from one bucket load of water.” He said they expected three-to-four drops, depending upon the size of the fire. “So, they were apprehensive at first telling us that they preferred us to drop the entire load and just refill and return. It took some educating and some positive results to show that this capability was an invaluable addition to their firefighting arsenal and from that point on they were asking for ‘split drops’ by name every time we rolled up on a fire. It had a huge impact on the support we were able to provide the Turkish crews on the ground and Turkish Fire Service and I don’t think there is another company out there that can provide that type of capability; it’s truly a game changer,” Hutchings said.

Maintenance

Tayler said that proper maintenance can be an asset to the product and can make it last longer. The product is made from, “a variety of materials, including heavy duty fabric coated with man-made rubber, specialty fiberglass stiffeners, heavy duty seat-belt type webbing, stainless steel cables, and aluminum valves and components,” said Tayler.

He said that the typical life expectancy is 10 years, but that some customers have maintained their bucket for up to 30 years. Regular inspections and maintenance will keep it operational, and helicopter operators are typically the inspectors. SEI does conduct maintenance on the product as well at their headquarters in Delta, British Columbia., or at authorized in-country locations. “Some customers treat their Bambi Bucket like gold; they store it in a hangar, dry it and inspect it. (Life durability) is dependent on how they care for the product.”

Tayler said that SEI Industries greatly values when new customers come to their location to receive training, and at that time, they learn how to maintain the product. We treat our customers well when they are on location, he shared. “They get the training at the factory, free of charge. Customers are certified in maintenance repair for the Bambi Bucket® once they take the training.

Use and applications

Wildfires and urban interface fires (where humans are present) are both good applications for the product. Although Tayler notes that there can be some debate as to using the product in an urban area.

“Some urban interface areas want a belly tank because there can be a risk that a bucket could be mistakenly released where a belly tank cannot. The belly tank is fully attached to the aircraft. The Bambi Bucket® can be on a hook and the pilot can release what is on the hook if they are in trouble. It is done in a controlled manner.”

He said that their reality with wildland firefighting is that the Bambi Bucket® is one of many tools in the toolbox of firefighting. “You’ll see some that want belly tanks, Bambi Buckets, or super tankers,” Tayler said.

As far as refilling the Bambi Bucket® during an active fire, Tayler says, “Lake, stream, river, pond, pool, or tank, use the one that is closest to the fire to maximize the number of drops per hour.”

Pilot training with the Bambi Bucket®

Regarding pilot training for the Bambi Bucket®, as noted earlier, when operators purchase the product, they can visit the headquarters and receive training, and learn about other products offered by SEI Industries that may be applicable to their jobs.

Conversely though, the U.S. Forest Service requires 1,500 hours before pilots can fly on fires. Pilots must also have training on flying slung loads and operating a Bambi Bucket®.

The pilot operates a switch mounted on the cyclic or collective to deploy the Bambi Bucket®. Military operators have a Bambi operator who controls the bucket from the back of the helicopter with hand-held controls while communicating with the pilot.

Technology changes and updates

Another long-term employee is Engineering Manager Mark Toeckes, P.E. He has been with the company for 18 years as well. He said he started designing for the Bambi Bucket® product line in 2009.

He said there have been many updates to the product, but two are worth noting. “The major technology thrust in recent times has been the integration of sophisticated electrical control systems to provide additional features to the buckets. While the end users want more features, they also want the product to be simple enough for them to operate and maintain.”

He cited, “Another change has been the increase in the average size of helicopters using Bambi Buckets®. Twenty years ago, the most popular bucket size was 120 U.S. Gallons (USG), while now it is 320 USG and sales of 2,000 USG buckets are commonplace. Often the technologies don’t simply scale up to larger sizes and different ways of doing the same job need to be invented.” He added that contracting agencies are using larger helicopters, so they can lift heavier Bambi Buckets®. He said that sales are increasing on the larger gallon models over the past five years.

Bambi Bucket love

Customer satisfaction, according to SEI Industries, is high regarding its Bambi Bucket®. Tayler said that customers show “huge appreciation.” He adds, “They see the helicopter with the Bambi Bucket® knocking down the fire in the community.” He notes that the Bambi Bucket® is one critical piece to fighting the fire, and that there is also “praise and appreciation for the whole system – the team fighting the fire, and the ground crews.”

Company Contact Information

SEI INDUSTRIES LTD. CORPORATE OFFICE

7400 Wilson Avenue

Delta, British Columbia

Canada, V4G 1H3

Toll Free: 1-866-570-3473

Phone: 604-946-3131

www.sei-ind.com

READ MORE ROTOR PRO: https://justhelicopters.com/Magazine

WATCH ROTOR PRO YOUTUBE CHANNEL: https://buff.ly/3Md0T3y

You can also find us on

Instagram - https://www.instagram.com/rotorpro1

Facebook - https://www.facebook.com/rotorpro1

Twitter - https://twitter.com/justhelicopters

LinkedIn - https://www.linkedin.com/company/rotorpro1