|

Jul

25

2022

|

|

Posted 3 years 204 days ago ago by Admin

|

|

When it comes to developing cleaner, greener propulsion systems for helicopters, the industry’s original equipment manufacturers (OEMs) are going green. “Helicopters account for less than 1% of global CO2 emissions but there are still ways that we can reduce that figure,” said Luca Cossetti, an innovative power solutions specialist with Airbus Helicopters. “We are committed to reducing our environmental footprint to get closer to the end goal of net-zero CO2 emissions.”

“Aviation, including the helicopter market, is under substantial pressure to progress its sustainability initiatives with more efficient engines and airframes,” added Nicolas Chabée, vice president of Sales & Marketing (Helicopter) with Pratt & Whitney Canada (P&WC). “Our priorities include designing more efficient engines with reduced fuel consumption and ensuring our customers know that their P&WC engines can fly on up to 50% sustainable aviation fuel (SAF) made from sources such as used cooking oil and algae.”

“Many companies and operators have ESG (environmental, social, and governance) plans in place that set specific targets for reduction in carbon emissions over time,” said Zach Dailey, Bell Textron’s chief engineer of innovation. “Providing clean alternatives for their helicopter fleets is where we can continue to help our customers meet their goals.” Here is a look at how six OEMs are making this happen.

Airbus Helicopters

When it comes to finding alternatives to fossil-fuelled rotorcraft, “Airbus Helicopters' long-term innovation roadmap involves exploring all options, brick by brick, and making incremental improvements towards zero emissions,” Cossetti said.

One way of doing this is through a combination of improved aerodynamics and weight reduction, which he said “can bring a reduction of CO2 emissions between 10% and 15%.”

A second method is turbine improvements and next generation thermodynamic cycles, which Airbus believes could reduce CO2 emissions between 10% and 25%. For instance, the company’s H160 has been able to reduce its fuel burn by 15%, thanks to its Arrano turboshaft powerplant made by Safran Helicopter Engines. “The Eco-mode in our helicopters (using one or two engines depending on the flight phase) could bring a CO2 reduction up to 15%,” said Cosetti. “The Racer demonstrator will shortly test this new feature in flight, with potential applications to other twin-engine platforms.”

Airbus Helicopters is also exploring “hybridization,” using a turbine engine and an electric motor together to reduce fuel burns in flight. “The first hybridization solution has already been tested in flight on our FlightLab H130 helicopter in 2021,” Cossetti said. “The results are promising, and pave the way to more powerful hybrid propulsion systems, already under assessment. All these improvements together, some of them already on the market, can drive up to 50% fewer CO2 emissions in the coming years.”

As for using SAF in their tanks, Cosetti said, “The entire Airbus Helicopters range is certified to fly on up to a 50% blend of SAF, which represents a 40% reduction in CO2 emissions alone. On 9 November 2021 we performed the first flight of a helicopter using 100% sustainable aviation fuel (SAF) in one of the two engines of an H225. This flight was the start of a flight campaign to assess the impact of unblended SAF on helicopter systems with a view to certifying the use of SAF blends that exceed the current 50% limit.”

In addition to these efforts, Airbus Helicopters is developing a fully electric-powered vehicle, the CityAirbus NextGen, that will be able to cover short distances with three passengers and pilot onboard. The company expects its first flight in 2023, with the goal of being certified for flight two years later.

Bell

Like Airbus, Bell is taking a multi-pronged approach to the question of cleaner, greener helicopter propulsion.

Much of its efforts are focussed on using SAF CO2 emissions now. This is why Bell began using SAF in its Bell Training Academy (BTA) and customer demonstration fleet aircraft last year. “We are the first rotorcraft customer to receive SAF supply from global aviation fuel supplier, Avfuel Corporation, and have worked closely with them to ensure a steady supply of SAF to our facilities,” said Dailey. (In its pure form, SAFs like Neste’s MY Sustainable Aviation Fuel™ can reduce greenhouse gas emissions by up to 80% compared to petroleum-based jet fuel.)

Bell has also announced that the Bell 525 has completed its first flight using SAF. Meanwhile, the company has teamed with Safran Helicopter Engines to explore technical performance and economic impacts of using SAF on the Arrius 2R-powered Bell 505. “A single, dedicated Bell 505 aircraft will conduct flights solely with the use of blended SAF,” Dailey said.

Bell is also hoping that its electrically distributed anti-torque demonstrator, known as EDAT, will reduce fuel burns as well as reduce tail rotor noise. The EDAT system is composed of four small fans with their own motors housed within a tail rotor shroud in an offset two-by-two pattern. The system is currently being test flown.

At the cutting edge of CO2 reduction technology is Bell’s Autonomous Pod Transport (APT). This is a tail-sitting, all-electric vertical takeoff and landing autonomous aircraft that transitions to on-wing flight to minimize noise and gto maximize battery capability, range, and payload. The unmanned APT is currently under development, and has been flown.

HyPoint

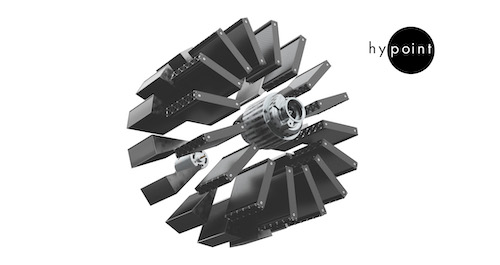

When it comes to aviation propulsion, HyPoint is in a class of its own. That’s because this company has developed a zero emissions hydrogen fuel cell system to power electric vertical take-off and landing (eVTOL) aircraft, a system that has won a 2020 NASA iTech Initiative award. (Fuel cells generate power that can be used to run electric motors.)

“HyPoint's revolutionary approach utilizes compressed air for both cooling and oxygen supply to deliver a high-temperature fuel cell system that is three times lighter than existing fuel cell systems — representing a total weight reduction of more than 60%,” explained HyPoint founder and CEO Dr. Alex Ivanenko. “Testing and modeling have shown that HyPoint's system can achieve up to 2,000 watts per kilogram of specific power, which is more than double the power-to-weight ratio of traditional hydrogen fuel cells systems and up to 1,500 watt-hours per kilogram of energy density, enabling longer-distance journeys.”

In August 2021, HyPoint partnered with Piasecki Aircraft to co-develop hydrogen fuel cell systems for eVTOL applications including its PA-890 Compound eVTOL Helicopter. If successful, the PA-890 will become the first-ever hydrogen-powered manned helicopter.

Also last August, HyPoint announced a new partnership with global chemical company BASF to develop a cutting-edge hydrogen fuel cell membrane that will ultimately increase HyPoint's system level power significantly as well as increase durability and operating temperature. The new system will be able to deliver at least 3,000 W/kg of specific power — a 50% increase — that’s enough to satisfy the requirements of virtually any eVTOL.

“In March 2022, HyPoint announced a partnership with Gloyer-Taylor Laboratories to integrate GTL's carbon-composite liquid hydrogen tanks with our hydrogen fuel cell system,” Ivanenko said. “The tanks have demonstrated a 75% mass reduction compared to existing state-of-the-art aerospace cryotanks, enabling hydrogen aircraft and eVTOL makers to store as much as 10 times more liquid hydrogen fuel without adding mass. As a result, aircraft can travel longer distances without refueling.”

Leonardo Helicopters

Leonardo Helicopters is another OEM that is researching multiple options for cleaner, greener helicopter propulsion. As such, it is considering all of the options outlined so far.

“We have four streams of R&D on this matter,” said Matteo Ragazzi, the company’s director of engineering. “The first stream is looking at conventional turboshafts and ways in which we can reduce their fuel consumption also through advanced power management solutions. The second is SAF, which is really low-hanging fruit for us. Our helicopters can already fly with a 50% SAF blend in their fuel, and we are heading towards 100%.”

The third propulsion stream being explored by Leonardo Helicopters is hybridization. The company would love to build all-electric long distance helicopters powered solely by batteries, but says that current lithium ion technology is not up to the task and a solution doesn’t seem to be on the horizon.

“Actually, the problem is not a technological issue in itself, but it is rather driven by manufacturing,” Ragazzi explained. “If you go to the battery suppliers, they are concerned with producing cells for the electric car mass market, rather than the comparatively small helicopter market. Therefore, their pursuit of increased power density is driven by automotive more than aviation, which means their battery cells are too heavy for practical helicopter long-distance applications and they are not interested in investing and researching for small quantities of high performance cells.”

Leonardo’s fourth stream is hydrogen. “We are interested in burning hydrogen directly to drive the turbines, or indirectly using electrical engines and hydrogen fuel cells,” Ragazzi said. “The first option is still very new, while the second is still facing weight, volume and thermal management issues associated with the fuel cells.”

“This is the roadmap we are following,” he added. “The fact that other OEMs are doing the same doesn’t surprise me, because we are all considering every available option.”

Pratt & Whitney Canada

As an engine OEM, Pratt & Whitney Canada (P&WC) can directly affect change when it comes to making helicopter propulsion cleaner and greener. This is exactly what they are doing.

For example, P&WC has signed a Memorandum of Understanding with Air BP to work towards using SAF up to 100% in Pratt & Whitney engines from now through 2024. “Neat SAF from a major integrated energy company that is highly focused on SAF initiatives enables the evaluation, testing, and validation needed to ensure that our engines are fully capable of operating with 100% SAF,” said Graham Webb, chief sustainability officer at Pratt & Whitney.

In November 2021, Pratt & Whitney Canada joined a long-term SAF pilot program with German air rescue operator ADAC Luftrettung and their fleet of H135 helicopters. The collaboration commits them to using SAF at blends of 30-40% over 36 months.

It’s worth noting that P&WC’s carbon offset service allows its engine users to offset the carbon footprint of their aircraft, by sourcing carbon offset credits from South Pole, a globally recognized carbon offset provider. This program is available for all P&WC-powered business jet, helicopter and regional aircraft customers enrolled in an Eagle Service™ Plan (ESP™) or Fleet Management™ Program (FMP™).

Sikorsky

Sikorsky is currently supporting S-76 and S-92 helicopter operators who are interested in using SAF blends. To this end, “Sikorsky conducted technical reviews in conjunction with engine manufacturers to give service letter guidance on use of biofuel in alignment with the FAA drop-in (fuels) approach under existing certification of Jet A fuel limitations,” said Sikorsky spokesperson John Dorrian. “The result is that 50/50 SAF fuel operation is currently permitted for both S-76 and S-92.” He added that S-92 operators such as CHC and Milestone have conducted demonstration flights using SAF fuel concentrations up to 50%.

As for other options? “We are actively developing powertrain electrification technologies but are not yet publicly sharing details,” Dorrian said. “We are publicly engaging in the developing Advanced Air Mobility (AAM) market and sharing our perspective on the current opportunities and challenges to achieving the full potential of this expansion of current helicopter missions in, around, and between cities.”

READ MORE MAY/JUNE ISSUE

READ MORE ROTORCRAFT PRO

WATCH ROTORCRAFT PRO YOUTUBE CHANNEL

You can also find us on

Instagram - https://www.instagram.com/rotorcraftpro/

Facebook - https://www.facebook.com/rotorcraftpro/

Twitter - https://twitter.com/justhelicopters