|

May

16

2022

|

|

Posted 3 years 285 days ago ago by Admin

|

|

Airbus Helicopters is making massive technology investments to develop data driven customer service, revolutionize manufacturing, enhance operational safety, and define the future of vertical lift.

Airbus Helicopters has operated for 30 years from Marignane, France. The company started as Eurocopter but was renamed to Airbus Helicopters in 2014. This spring, they’ve announced massive changes to new aircraft, customer support and training, and the integration of the newest technology in modern helicopters.

Airbus Helicopters has its main assembly facilities in France and Germany and a worldwide presence with 31 customer centers and affiliated sites in locations such as Brazil, Australia, Spain, United States, Romania, and the United Kingdom. The North American Customer Support division has new leadership in Niko Szodruch for its 800 customers, operating from Grand Prairie, Texas. He came from the company’s global helicopter maintenance and retrofit business and is leading in development of a strategic service plan for North America. The H125 is the best-selling helicopter in the world and there are 30 produced each year from Columbus, Mississippi. The volume of helicopters sold varies year-over-year, but in 2021, they sold 419 units to both civilian and military markets.

Introducing the Airbus H160

After seven years of design and engineering, the Airbus H160 Helicopter is ready for primetime. Gilles Armstrong, head of the H160 program at Airbus Helicopters said, “Industrial ramp up is a big deal; the ability to assemble quickly, a feature in the car industry, requires a lot of upstream design and decision making.” The H160 has been produced in an innovative new manner using major component assembly (MCAs) across diverse European locations with digital production automation. Some of the automation includes:

• Digital and paperless shop floor

• Flow line

• Robotics

• 3D, digital technical publications

Components are made in France, Spain, and Germany, which the company said leads to faster integration for custom orders. The entire H160 can be produced within 40 days with the new model. A company video titled; “Building Blocks” suggests that they’ve created a new industrial revolution in helicopter manufacturing. Their goal is to focus on the building blocks of better agility, quality, standardization, and competitiveness in the production of the helicopters. They share, “Building helicopters in the digital age, different parts of the helicopter are produced and assembled from different locations – in parallel,” said program ambassadors in the video, tagging this new model as the “HGeneration” of products.

With all new aviation developments and technologies comes rigorous certification processes. The H160 is no different, and they’ve already taken the product through certification with the European Union Aviation Safety Agency (EASA), National Civil Aviation Agency, Brazil (ANAC), and Japan Civil Aviation Bureau (JCAB). They are working on final testing and validation with the U.S. Federal Aviation Administration (FAA).

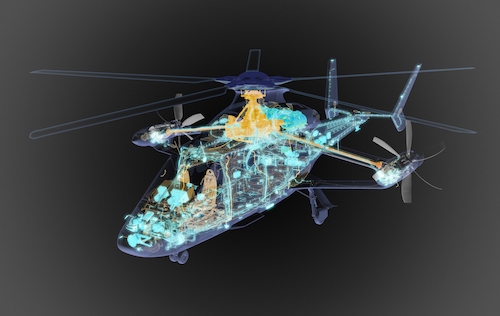

An update on the Airbus RACER

If it’s speed you are seeking, look no further than the Airbus Rapid and Cost-efficient Rotorcraft (RACER). By year end, it will complete its first flight demonstration. The helicopter’s release was pushed back due to the pandemic and supply chain issues. But its assembly, being completed in Marignane, is now well underway.

The helicopter was funded through a European government grant worth $227 million (200 million euros) called Clean Sky 2 which was a research initiative involving 13 European countries, 40 companies, and university partners.

The lightweight and fast civilian aircraft can be leveraged for many missions:

- Search and rescue

- Commercial transportation

- Public service

- And emergency medical support

It uses 15% less fuel per nautical mile at 180 kts (normally 130 kts). Assembly began in Germany with a metallic and composite airframe with the main structure being made from additive manufacturing. Safran has provided the eco-mode hybrid-electric system which allows for one of the two Aneto engines to be switched to standby during cruise flights.

Flightlab shaping the future of helicopter technology

Started in April 2020, the Flightlab within Airbus Helicopters started shaping the future. It provides insights through training and testing on:

- Situational awareness

- Noise and fuel consumption reduction

- Rotor strike alerting system (RSAS), which alerts crew to collision risks

- Optronics system with fly-by-wire autopilot and heads-up display

- Health and use monitoring system (HUMS)

The H130 is the choice rotorcraft for the Flightlab because of the wide cabin, quiet operations, and payload capabilities. It will also be the platform to test the Vertex project.

Grazia Vittadini, former chief technology officer at Airbus said, “We are excited by the potential that the Vertex demonstrator project has to offer. By using our platform-agnostic flying laboratory to mature these technologies, we have an agile and efficient test bed that will support the development of future autonomous systems that could later equip Airbus’ current helicopter range and (e)VTOL platforms.” Included on the aircraft is an Engine Backup System (EBS) that provides electrical power to the main gear box in case of engine failure.

The Flightlab is also testing:

- Autonomous missions, obstacle avoidance

- Vision based sensors

- High performance computing capabilities

- Advanced image processing technology

- Automatic approaches to land anywhere

Physically, the helicopter’s exterior houses what looks like an inverted light bulb on the bottom of the aircraft. Imagery and control for the mission is provided through an iPad and managed by a crew member on the aircraft along with two other pilots.

Airbus is hopeful that the testing will reveal better:

- Rotor speed management

- Blade design

- Noise reduction

Airbus Helicopter’s Flightlab is a comprehensive aircraft with ambitious goals to change future rotorcraft for the better.

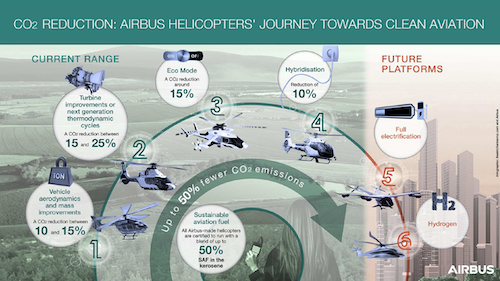

Reduction of carbon emissions through the development of Sustainable Aviation Fuels (SAF)

Stefan Thome, executive vice president, engineering and chief technical officer, Airbus Helicopters, said, “While all Airbus helicopters are certified to fly with up to a 50% blend of SAF mixed with kerosene, it is our company’s ambition to have its helicopters certified to fly with 100% SAF within the decade. Today’s flight is an important first step towards this goal.”

While cooking oil (think French fries) can be used in SAF, the idea is to use a blend of different oils. Currently they are receiving SAF from TotalEnergies, which offers 90% Co2 reduction compared to regular jet fuel.

“SAF is an important pillar of Airbus Helicopters’ decarbonization strategy because it provides immediate Co2 reduction with no negative impact on the performance of the helicopter,” Thome added. “I thank our partners Safran Helicopter Engines and TotalEnergies for their important collaboration in making today’s flight a reality. Further cooperation among all industry stakeholders is essential to overcome the challenges associated with implementing SAF widely and to make real progress in reducing the aviation industry’s Co2 emissions.”

Probably the biggest industry news regarding SAF is the development of a SAF User Group in the rotorcraft community. Eligibility for participation in the group is broad:

- Airbus Helicopters

- Engine OEMs

- Energy Suppliers

- Industry Associations

- Customers

- International standards organizations

Airbus ultimately wants to bring the industry together to drive development of this important new technology. 100 Airbus Helicopter customers are in the SAF user group and have registered and want to be involved. The goal is to reach scalability.

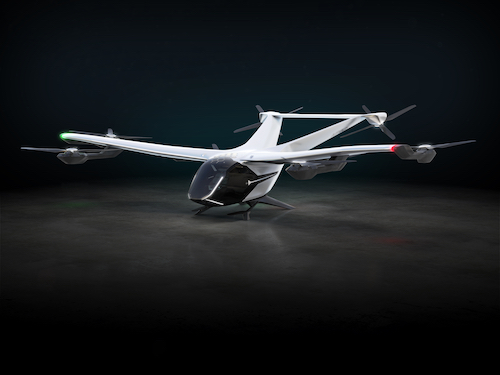

Urban Air Mobility - CityAirbus NextGen

Airbus is leading the charge for urban air mobility, and they are cautiously optimistic. Airbus is working on Vertex for part of the technological development. But leaders say that while the technology continues to develop, there are many factors at play before we see CityAirbus NextGen flying around.They mention things like safe integration of aerospace corridors and community adoption of autonomous flight, for example.

CityAirbus NextGen, it is a four person aircraft with eight propellers. It offers a quiet flight at 65-70 dbA (about the impact of a range hood over a stove), with a flight range of 80 km (just under 50 miles), and speed of 120 km/h (equivalent to 75 miles per hour).

Head of UAM Strategy Execution & Partnerships for Airbus, Balkiz Sarihan, recently cited a study by EASA from May 2021: 83% of respondents showed a positive attitude towards UAM, 71% ready to use it.She said concerns that respondents have are safety, security, noise, and impact on wildlife. Currently they are writing eVTOL certification standards to ensure safety for future aircraft.

They are also testing in the Paris ecosystem. Sarihan said, “Airbus, ADP, RATP and other key stakeholders in the Paris region have come together to drive the development of this new mobility service. This partnership gives us access to assets, like the Pontoise sandbox to test the conditions of public acceptance in this ecosystem. This is also a major opportunity to build on the Airbus site specialization, by leveraging the expertise of Airbus Paris le Bourget site for NextGen’s blades for example.”

Customer Service and Support

In an era of lackluster support with many American companies, it is refreshing to hear about Airbus Helicopters’ ramped-up plans to support their customers.

New customers or customers taking delivery of a new aircraft type in their fleet will fall into the category of HCare Initial. Current customers already operating Airbus helicopters are oriented toward HCare In-service, while HCare Lifetime is for customers looking to start a long-term service collaboration with Airbus.

EVP of Support and Services, Christoph Zammert recently reported on the company statistics to provide perspective on the scope of customer service with Airbus Helicopters:

- There are 3,111 operators

- 12,012 helicopters in-service

- 153 countries

- 5,000 employees at Airbus

- 2,500 helicopters covered by global support contracts

- 1,500 connected helicopters

- 31 customer centers and affiliated sites

- 5 technical support hubs (France, Germany, USA, Singapore, Mexico)

- 92 service centers

- 18 training and simulation centers

- 85% of operators own less than five helicopters

With operators in so many diverse locations, the company has set up AirbusWorld, an online customer platform.

Concurrently, the H160 entered service with an innovative support concept that is highly digital. With the industry’s first computerized rotorcraft flight manual, H160 pilots can access everything they need right on an iPad in the cockpit.

They can create a flight plan on the iPad and reference the user manual within the program. In the same vein, H160 technicians have access to new generation technical documentation featuring 3D illustrations, and engine maintenance aligns with general aircraft maintenance. Moreover, there is clear communication between the operators and Airbus Helicopters in that data transfer from the aircraft is automatic.

Finally for U.S. customers, there is new customer support leadership in Niko Szodruch. He is responsible for supporting more than 800 customers across the region while leading development of the strategic service plan in North America. Szodruch formerly oversaw the global helicopter and retrofit business for Airbus Helicopters.

In summary, Airbus Helicopters is making long bets and investing in new technologies that they believe will improve the helicopter and eVTOL industry. Will these investments change the helicopter industry for the better and pay off? If the past is prologue, I would not bet against them!

READ MORE ROTORCRAFT PRO

WATCH ROTORCRAFT PRO YOUTUBE CHANNEL

You can also find us on

Instagram - https://www.instagram.com/rotorcraftpro/

Facebook - https://www.facebook.com/rotorcraftpro/

Twitter - https://twitter.com/justhelicopters