|

Feb

28

2022

|

|

Posted 3 years 352 days ago ago by Admin

|

|

VIEW VIDEO FEATURE

The employee commitment at Erickson Inc. is like that of a great sports team. The employees are the athletes, the coaches, and even the fans. The term “bad ass” is thrown around amongst employees. They proudly display the company colors and act upon the company culture with personal commitment. In 50 years of business, Erickson has become legendary as an original equipment manufacturer (OEM), maintenance, repair, and overhaul (MRO) operation, and as an aerial services company.

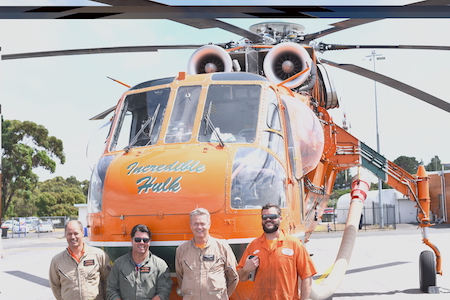

A common phrase heard among Erickson employees is “bleeding orange,” which demonstrates the team’s tenaciousness and drive for safety and service. With nearly 800 employees working worldwide, they strive to save both people and property through aerial firefighting and defense missions, while accomplishing civil aviation services with heavy-lift helicopters. They do this with capable hands and an eye on the mission.

The cornerstone of the company is aerial firefighting with the S-64 Air Crane® helicopter, but Erickson offers many other important industrial and lifesaving services.

If there was ever a mission as serious as that of military operations, it would be the work that Erickson does on a day-to-day basis in countries like the United States, Greece, Italy, Korea, and Australia.

Like most companies, Erickson Inc. has had its ups-and-downs. They’ve had to fight for principles while drive through market restrictions and competition. They’ve had to prove their mettle repeatedly on the world stage. After 50 years, Erickson has had a few bumps and bruises, but it has withstood the challenges and has grown to thrive. The future is coming— and it’s orange.

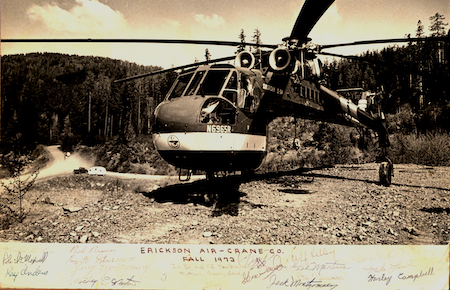

Launching the company in 1971

Jack Erickson, founder of Erickson Air-Crane (now known as Erickson Incorporated) was born into a family of entrepreneurs. Erickson’s father owned a logging company. With family roots in logging, Jack Erickson was determined that there should be a better way to log mountaintops. in 1969, Erickson started talking with his friend, Wes Lamatta , about establishing a timber harvesting pilot program using helicopters with the U.S. Forest Service. (Lamatta later founded Columbia Helicopters.) They thought that helicopters would be the best way to access the land and off-load the massive logs. Erickson started with a Sikorsky S-61 on a lease, and then started using the Sikorsky CH-54 Skycrane helicopter, and Lamatta used the Boeing 234 Chinook, a large tandem, rotor-wing helicopter.

Erickson bought a Skycrane, and then one more for the logging business. Billy Johnson, chief engineer at Erickson Inc., has been with the company for 16 years. “They pioneered that thing” he said about Erickson and Lamatta creating heli-logging.

According to Johnson, once Jack Erickson found out that Sikorsky was no longer going to support their aircraft, he said, “You are going to support me with parts, or sell me the type-certificate so that I can do it myself.” said Johnson. Decades later, in 1992, he obtained the type certificate from Sikorsky for the Skycrane. He later renamed the aircraft as the S-64 Air Crane® helicopter.

Erickson Air-Crane was founded in 1971 with the intention of adding powerline construction and aerial firefighting. Fast forward to today, Johnson says, “We are an OEM and repair station, and also an operator. These are three things that don’t necessarily go together, but we do them.”

Erickson’s Current Services

Today’s business is robust and diverse. Here are Erickson Inc.’s four areas of business and their sub-sectors:

Aircraft sales

Defense and national security

Air operations

Legacy fleet sustainment

Active contracts

Civil aviation

Aerial firefighting

HVAC and specialty construction

Oil and gas industry support

Powerline construction

Timber harvesting

AeroSystems manufacturing and MRO

OEM capabilities and services

MRO manufacturing and after-market capabilities

Research and development

Chris Erickson, senior quality manager (no relation to Jack Erickson) has been with the company since 1981 . He said that the business “evolved over decades by being an operator, then maintainer, then type-certificate holder; and then a support organization for the S-64 Air Crane® helicopter, worldwide.” The senior quality manager shared that a milestone for the company happened when Jack Erickson developed the fire tank in 1992 for aerial firefighting. He said that it was the first rotorcraft with a fire tank.

Chris Erickson has stayed with the company for 40 years and watched its evolution. Why has he worked so long for Erickson? “It is the people. I enjoy the challenges; there is always something new.”

He added that there has been immense pride in accomplishments over the years: “…the construction work, the development of the fire tank, the sale of aircraft internationally, the support of the aircraft, along with worldwide recognition by international governments – (it) has been impressive.”

Company Culture

The company’s culture is emphasized repeatedly by employees. There is something unique about it that keeps employees from leaving, even though there has been some turbulence with the business going public, going back to being privately held, going through bankruptcy. Through it all, Erickson employees continued to innovate and grow markets.

Jeff Mecklenburg, Erickson Inc.'s vice president of AeroSystems, said about the company culture, “(It is) a get-it-done culture – tenacious and gritty. We always find a way to get things done.” He added that when the company moved into becoming an OEM and added support services, they were at a milestone again. He cited the purchase of the type-certificates from Sikorsky and the decision to sell aircraft.

He said, “there is a loyalty to the aircraft in the field. Bleeding orange for me is to do anything for the company, anytime; get it done.” After 24 years with the company, he also said that the people are the reason he stays. He enjoys the unique work that the company does with the Air Crane helicopter from moving rhinos in Malaysia to delivering snow to the Vancouver 2010 Winter Olympics.

A common theme heard from employees is that they enjoy showing up to work every day because of the people they work with and the work they do. Amanda Hammerschmith, blade shop manager, said, “When you actually work for a company that saves lives, that’s pretty amazing.”

Type Certificates and Legacy Support

Erickson has developed legacy fleet support since 1992. The early purchase of the Sikorsky type certificate in 1992 for the Skycrane (later dubbed the S-64 Air Crane®) helicopter was just the beginning. Most recently in 2020, Erickson purchased the type certificates from Bell for the 214 B/B1 and 214ST. Owning the type certificates means that Erickson can manufacture parts, maintain the aircraft, and create new aircraft as an OEM. Owners and operators of these aircraft can come to Erickson for support.

Ownership and Employees

In today’s world, people often change jobs. It is a unique company when you hear about employees staying on for 10 and 20+ years. But at Erickson, that is the case. Many long-term employees cite two reasons for staying with the company:

Mission – the array of diverse and fulfilling projects

People – the commitment to their co-workers

Steve Reavis has been with the company for 31 years and now works as the commercial sales manager. He said he has had many positions during his tenure at the company, and now works with customers on civil projects to set up the movement of television antennas across mountains, HVAC unit lifts onto massive warehouse facilities, timber harvesting, and even cargo transport for the oil and gas industry. He said, “Erickson’s services, as an organization, are to provide best in-class service for both manufacturing and aviation operations to the specialized industry, including firefighting, heavy-lift, general support manufacturing of both platforms and outside capabilities.” The work is diverse, as he has been able to secure many heavy-lift, high-impact projects over the years.

He added that inventions, such as the anti-rotation system developed by Jack Erickson in 1974, was an asset to the S-64 Air Crane® helicopter and for the company. “This allowed the aircraft to perform short-rigging with better control than using long, line- spinning operations. The development of the fire tank, which was developed for a market that didn’t exist at the time—everyone was using buckets—Erickson was on the front of that development,” Reavis said. “Erickson has developed a global market with a platform that has shown itself to the world. We are the largest S-64 operator in the world.”

Regarding the “bleed orange” culture, Reavis said that the meaning is in execution, “the organization was strongly based upon the core values of the people. Everyone was willing and able to step out and show the capabilities of the organization. ‘Bleed orange’ shows that employees can execute on capabilities. They are strong, capable, and willing.”

Future Innovations

The aerospace industry must take time with new innovations. It is well known that the creation of new aircraft and changes to existing models can be deliberately slow because the safety of pilots and passengers is at stake.

With Erickson, they are preparing to re-invent the S-64 Air Crane® helicopter. The working name of the new vehicle is the F+.

Some of the innovative technologies will include:

Engine upgrade and modernization

Sikorsky’s MATRIX™ Technology

Enhanced water cannon

Composite Main Rotor Blades (CMRB)

In 2020, the development of CMRB was completed and approved by the FAA, and Erickson started rolling them out to existing models. They offer a lighter, more streamlined flight and are more fuel efficient than traditional metal rotor blades (see the sidebar for more information). The “enhanced water cannon” has also been going through testing and prototyping and should be ready soon. Stay tuned for more innovations from Erickson like night vision goggles, and autonomous technology that allows the S-64 to safely conduct nighttime firefighting.

Summing Up

Just like a winning team, Erickson, Inc. is beloved by employees, customers, and the helicopter industry. They have committed themselves to worldwide service using a variety of helicopters in their fleet. The sentiment is that the company “bleeds orange” because of its grit and the drive for each employee to remain committed to each other and the mission.

Erickson’s Invention of Composite Main Rotor Blades

In 2011, Erickson realized that the main rotor blades, nearing 40 years old, on the S-64 Air Crane® helicopters, were dated and needed to be replaced. Traditional aluminum blades were difficult and expensive to manufacture. They knew there had to be a better way.

Blade Shop Manager Amanda Hammerschmith (10-year employee) has worked on the project for years. Early on, Erickson worked to partner with others to develop the blades, but eventually found that they needed to bring it in-house if it was going to be completed.

“There’s nothing too big for us, Erickson can accomplish anything, there’s nothing this company can’t handle,” Hammerschmith said.

Erickson Chief Engineer Billy Johnson said, “Erickson’s composite main rotor blade (CMRB) program is the type of complex project typically done only at much larger manufacturers. Our work on the CMRB reflects a level of sophistication here at Erickson that the aerospace and manufacturing industries are becoming much more aware of now.”

Over 10 years, with 60 employees and involvement from a variety of departments (and 3rd party organizations) , new blades were created. Hammerschmith said, “We developed a brand-new blade that no one else had. We have a full composite blade that has done wonders for the company with efficiency, fuel, and lift. At the Blade Shop we hand lay-up the spar, it is an amazing project, and it is very worth it for our company.”

The CMRBs are installed on the S-64 Air Crane® helicopters for both the Erickson fleet and for owner/operators of other helicopters.

For more information about Erickson Inc. visit https://ericksoninc.com/

TO READ MORE ROTORCRAFT PRO JAN/FEB 2022 ISSUE